Buchholz Relay Principle

Introduction

In the realm of electrical engineering, safeguarding transformers against faults is paramount to ensure the smooth operation of power systems. One crucial component in transformer protection is the Buchholz Relay. This device, named after its inventor Max Buchholz, serves as an early warning system for internal faults within transformers, helping to prevent potential catastrophic failures.

Throughout this guide, we’ll delve into the intricate workings of the Buchholz Relay, exploring its history, functionality, applications, installation, maintenance, benefits, comparisons with other protection methods, and future trends.

History of the Buchholz Relay

The Buchholz Relay has a rich history dating back to the early 20th century. Max Buchholz, a German engineer, introduced this innovative device in 1921 as a means to address the growing concerns surrounding transformer failures.

At the time of its inception, transformer protection relied primarily on rudimentary methods such as fuses and overload relays. However, these methods proved inadequate in detecting and mitigating internal faults, leading to frequent disruptions and costly repairs.

Buchholz’s breakthrough invention revolutionized transformer protection by introducing a sophisticated yet elegant solution. The relay was initially designed to detect oil flow abnormalities within transformers, which often indicate the presence of internal faults such as insulation breakdown or partial discharges.

Over the decades, the Buchholz Relay underwent significant advancements, evolving into a highly reliable and efficient component of modern transformer protection systems. Its widespread adoption across various industries underscores its enduring relevance in electrical engineering.

How Does the Buchholz Relay Work?

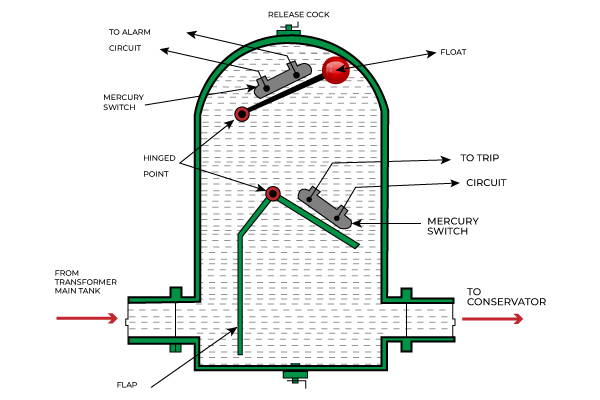

At its core, the Buchholz Relay operates on a simple yet ingenious principle: the detection of gas accumulation within the transformer’s oil-filled tank. This gas buildup occurs as a result of internal faults, such as arcing, overheating, or insulation breakdown, which produce hydrogen and other combustible gases.

The relay consists of two main components: a float chamber and a mercury switch. Suspended within the transformer’s oil reservoir, the float chamber contains a hinged float that moves freely with changes in oil flow.

During normal operation, the float remains in a neutral position. However, when gas accumulates due to an internal fault, the float rises, indicating a deviation from the usual oil flow pattern. This movement triggers the mercury switch, which in turn activates alarm or tripping mechanisms, signaling the presence of a fault.

The sensitivity of the Buchholz Relay can be adjusted to detect varying degrees of gas accumulation, allowing for early intervention before the fault escalates into a major issue. Additionally, modern variants may incorporate electronic sensors for enhanced reliability and remote monitoring capabilities.

Applications of the Buchholz Relay

The Buchholz Relay finds widespread use in transformer protection across diverse industries, ranging from power generation and distribution to industrial manufacturing and transportation.

Protection Against Internal Faults

One of the primary functions of the Buchholz Relay is to detect and mitigate internal faults within transformers. These faults pose significant risks, including insulation damage, overheating, and potential fire hazards. By promptly detecting gas accumulation, the relay enables operators to take corrective actions, such as isolating the faulty transformer from the grid and conducting necessary repairs.

Types of Transformers

The Buchholz Relay is typically employed in oil-filled transformers, including distribution transformers, power transformers, and instrument transformers. Its versatility and reliability make it a preferred choice for safeguarding critical assets in electrical infrastructure.

Advantages and Limitations

Advantages

- Early Fault Detection: The Buchholz Relay provides early warning of internal faults, allowing for timely intervention and prevention of equipment damage.

- Cost-Effectiveness: Compared to alternative protection methods, the relay offers a cost-effective solution with minimal maintenance requirements.

- Compatibility: It can be seamlessly integrated into existing transformer installations, enhancing overall system reliability without significant modifications.

Limitations

- Dependence on Oil-Filled Transformers: The Buchholz Relay is designed specifically for oil-filled transformers, limiting its applicability to dry-type or gas-insulated transformers.

- Sensitivity to External Factors: External disturbances such as vibration or oil turbulence may trigger false alarms, necessitating careful calibration and monitoring.

In the next section, we’ll explore the installation and maintenance considerations for the Buchholz Relay.