Transformers play a crucial role in our electrical systems, allowing us to efficiently transmit and distribute power. Understanding how transformers work and their basic principles can help us appreciate their significance. This article delves into the essentials of transformers, including their history, construction, and applications.

What is a Transformer?

Definition of a Transformer

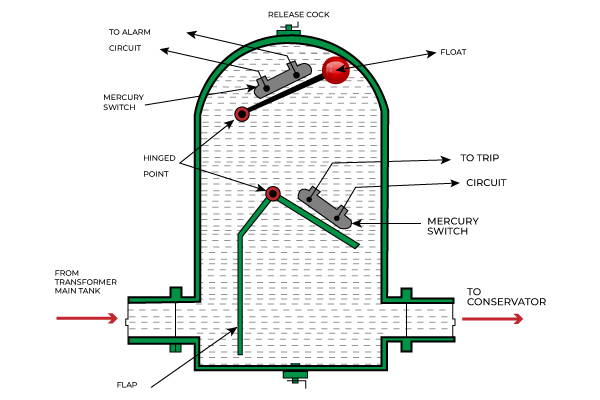

A transformer is an electrical device that transfers electrical energy between two or more circuits through electromagnetic induction. It consists of a core and windings, which work together to change voltage levels and provide isolation between circuits.

A transformer is a static device and it has no rotating parts. So, the maintenance of a transformer is quite easy. It is widely used globally for transmission, distribution and generation site. So, for an electrical engineer, it is quite important to have an in-depth knowledge about transformer.

In this blog post, you will be able to know the Basic components of a transformer, types of transformers, History, and different laws and equations of a transformer.

Basic Components of a Transformer

- Core: The core is usually made of laminated silicon steel to minimize energy losses. It serves as the magnetic path for the transformer.

- Windings: Transformers have primary and secondary windings made of copper or aluminum. These windings are coils of wire wrapped around the core.

Types of Transformers

Transformers come in various types, each serving a specific purpose. Here are the main types:

- Step-up Transformers: Increase the voltage from primary to secondary windings.

- Step-down Transformers: Decrease the voltage from primary to secondary windings.

- Isolation Transformers: Provide electrical isolation without changing voltage levels.

- Autotransformers: Use a single winding to act as both primary and secondary, providing a more compact design.

- Instrument Transformers: Used for measuring voltage and current, including current transformers (CTs) and voltage transformers (VTs).

History and Development of Transformers

Early Discoveries and Inventors

The transformer concept dates back to the 1830s when Michael Faraday discovered electromagnetic induction. This principle laid the foundation for transformer technology. Later, in the 1880s, Nikola Tesla developed practical transformers that we use today.

Evolution of Transformer Technology

Over the years, transformer design has evolved significantly. Early transformers were large and inefficient, but advancements in materials and engineering have led to more compact and efficient designs. Today, transformers are critical components in power grids, enabling efficient electricity transmission over long distances.

Modern Advancements

Recent innovations focus on improving efficiency and sustainability. Modern transformers use advanced materials like amorphous steel and nanocrystalline cores, which reduce energy losses. Additionally, smart transformers with monitoring capabilities are being developed to enhance grid reliability.

How Does a Transformer Work?

Explanation of Electromagnetic Induction

Transformers operate based on electromagnetic induction, a process where a changing magnetic field induces an electric current in a conductor. Faraday’s Law of Induction explains this phenomenon:

“The induced electromotive force in any closed circuit is equal to the negative of the time rate of change of the magnetic flux through the circuit.”

Role of Primary and Secondary Windings

The primary winding receives the input voltage, creating a magnetic field in the core. This magnetic field induces a voltage in the secondary winding, which can be higher or lower than the input voltage, depending on the transformer’s design.

The function of the Transformer Core

The core concentrates the magnetic field and provides a low-resistance path for the magnetic flux. This enhances the efficiency of the induction process. The core’s material and construction significantly impact the transformer’s performance.

Step-by-Step Process of Voltage Transformation

- AC voltage applied to primary winding: The alternating current (AC) creates a changing magnetic field in the core.

- The magnetic field induces a voltage in secondary winding: The changing magnetic field induces an AC voltage in the secondary winding.

- Voltage transformation: Depending on the turn ratio between the primary and secondary windings, the output voltage can be either stepped up or stepped down.

- Output voltage delivered: The transformed voltage is then delivered to the load connected to the secondary winding.

Electromagnetic Induction

Principles of Electromagnetic Induction

Electromagnetic induction is the process of generating an electric current from a changing magnetic field. This principle is the cornerstone of transformer operation. Faraday’s experiments demonstrated that a voltage is induced in a coil when exposed to a changing magnetic field.

Faraday’s Law of Induction

Faraday’s Law states that the induced voltage in a circuit is proportional to the rate of change of the magnetic flux. This means that faster changes in the magnetic field induce higher voltages. Transformers exploit this principle to transfer energy between circuits.

Application in Transformers

In transformers, electromagnetic induction allows for the efficient transfer of electrical energy. The alternating current in the primary winding creates a changing magnetic field, which induces a corresponding voltage in the secondary winding. This process is efficient and reliable, making transformers essential for power transmission and distribution.

Primary and Secondary Windings

Description of Windings

Transformers have two main windings: the primary and secondary. The primary winding is connected to the input voltage source, while the secondary winding is connected to the output load. These windings are made of copper or aluminum and are insulated to prevent short circuits.

Difference Between Primary and Secondary Windings

The primary winding receives the input voltage and generates a magnetic field. The secondary winding, placed in close proximity to the primary, receives the induced voltage. The number of turns in the windings determines the voltage transformation ratio. A higher number of turns in the secondary winding results in a step-up transformer, while fewer turns result in a step-down transformer.

How Windings Affect Voltage Transformation

The voltage transformation ratio is directly proportional to the ratio of the number of turns in the primary and secondary windings. If the primary winding has 100 turns and the secondary winding has 200 turns, the voltage is doubled in the secondary winding. Conversely, if the secondary has 50 turns, the voltage is halved.

Transformer Core

Role of the Core in a Transformer

The core is central to a transformer’s efficiency. It serves as a conduit for the magnetic flux generated by the primary winding. A well-designed core minimizes energy losses and enhances the overall performance of the transformer.

Materials Used for Transformer Cores

Traditionally, transformer cores are made of laminated silicon steel to reduce eddy current losses. Modern transformers may use advanced materials like amorphous metal and nanocrystalline alloys, which offer better performance and reduced losses.

How the Core Enhances Efficiency

The core’s design and material composition significantly impact the transformer’s efficiency. Laminated cores reduce eddy currents, while high-permeability materials improve magnetic flux conduction. These factors contribute to lower energy losses and higher efficiency in power transmission.

Types of Transformers and Their Applications

Overview of Various Transformer Types

Transformers come in various designs, each suited for specific applications. Understanding these types helps in selecting the right transformer for a given purpose.

Detailed Description and Applications

- Step-up Transformers: Used in power plants to increase the voltage for long-distance transmission, reducing energy losses.

- Step-down Transformers: Found in residential and commercial areas to reduce the high transmission voltage to usable levels.

- Isolation Transformers: Provide electrical isolation between circuits, often used in medical equipment and sensitive electronics.

- Autotransformers: Compact and efficient, used in voltage regulation and motor starting applications.

- Instrument Transformers: Include current transformers (CTs) and voltage transformers (VTs), used for measuring and monitoring electrical parameters in power systems.

Use Cases in Different Industries

Transformers are vital in various industries, from power generation and distribution to manufacturing and telecommunications. They ensure safe and efficient voltage levels, enhancing the reliability and performance of electrical systems.