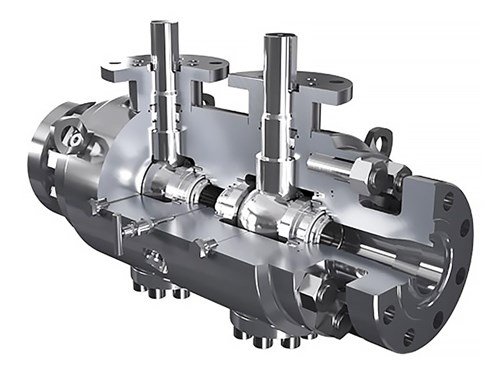

Have you ever wondered about the inner workings of a block valve? Well, you’re in luck because today we’re going dive into the fascinating of block valves. These essential components play a crucial role in controlling the flow of liquids or gases in a variety of systems. So, if you’re curious to learn more about how blocks work and the different types available, keep reading to satisfy your thirst for knowledge!

Block Valves Operate According to the Following Principle:

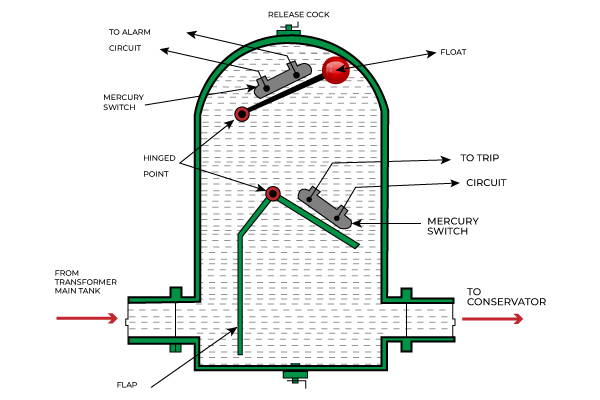

One of the primary functions of a block valve is to detach a portion of a pipeline from the rest of the system so that maintenance or repair work may be performed on that segment without impacting the system as a whole. When the valve is closed, it produces a physical barrier that stops the passage of fluid through the pipeline. This prevents obstructions from occurring. This enables the operator to operate on the equipment in a secure manner, without the possibility of any leaks or spills occurring.

There are several different methods that may be used to operate block valves. These mechanisms include manual, pneumatic, hydraulic, and electric mechanisms. The fundamental idea is the same regardless of the technique that is currently being utilized. A seal is formed when the valve is closed, which stops the flow of fluid from passing through the valve. When the valve is opened, the seal is broken, and the fluid is able to go through the pipeline.

Different kinds of block valves are as follows:

There is a wide variety of block valves accessible, each of which has its own set of characteristics and advantages that are exclusive to it. The following are some of the most frequent types:

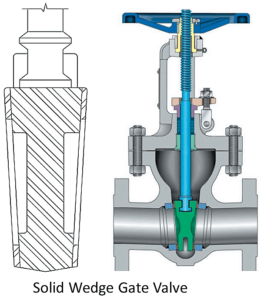

1. Valves for the Gates:

The industry makes extensive use of a variety of block valves, one of the most prevalent of which is the gate valve. As a means of controlling the flow of fluid, they are equipped with a gate or wedge-shaped disk that can move up and down. It is possible for the fluid to get through the gate because the gate is lifted when the valve is open. The gate is lowered when the valve is closed, which results in the formation of a seal that puts a stop to the flow of fluid.

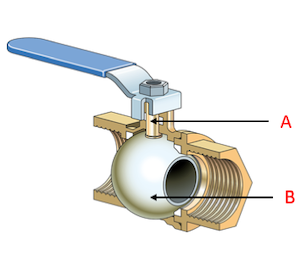

2. Valves with Balls:

Other types of block valves include ball valves, which are characterized by the utilization of a disk in the shape of a ball to regulate the flow of fluid. Whenever the valve is in the open position, the fluid is able to travel through the hole that is located in the middle of the ball. Following the closing of the valve, the ball will rotate in order to obstruct the flow of fluid.

3. Butterfly Valves:

Controlling the flow of fluid is accomplished by butterfly valves by the use of a disc that revolves around a central axis. After the valve has been opened, the disc is rotated in a direction that is parallel to the flow of fluid, which enables the fluid to pass through. The disc is rotated in a direction that is perpendicular to the flow of fluid when the valve is closed. This creates a seal that prevents the passage of fluid.

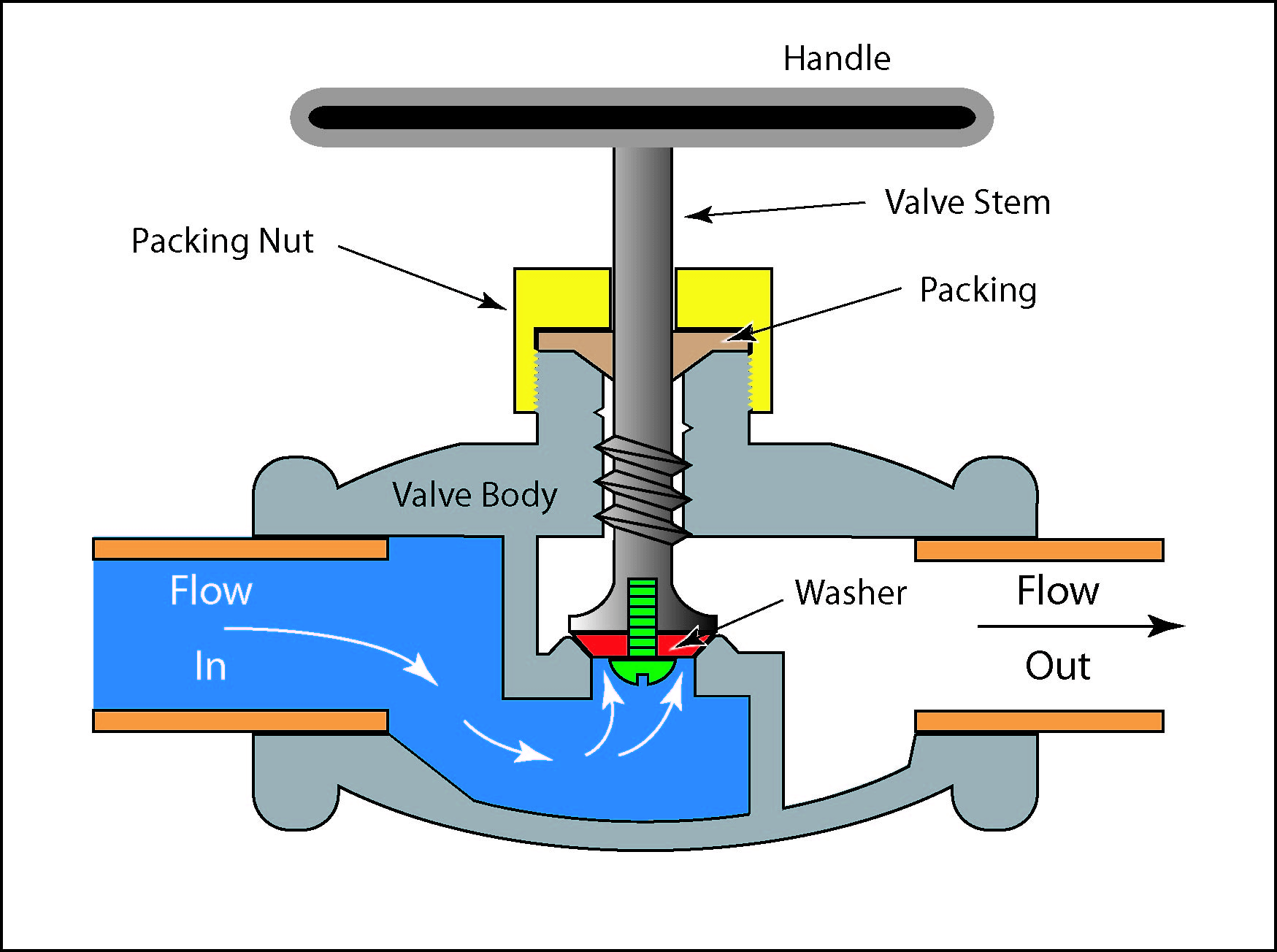

4. Globe Valves:

To control the flow of fluid, globe valves are constructed with a disk that may move in both an upward and downward direction. After the valve has been opened, the disc is lifted, which enables the fluid to go through the opening. In order to prevent the flow of fluid, the disc is lowered throughout the process of closing the valve.

5. Needle Valves:

Certain applications need for exact control of the flow rate, and needle valves are utilized in those situations. They feature a needle-shaped disk that is long and tapered, and it is designed to fit into a seat in order to control the flow of fluid. After the valve has been opened, the needle is lifted, which enables the fluid to go through the opening. Following the closing of the valve, the needle is lowered in order to produce a seal.

For Website Expert Click Here

For more tools-related info Click here