Introduction

SCADA (Supervisory Control and Data Acquisition) systems play a crucial role in the management and operation of power plants. These systems allow for real-time monitoring, control, and data acquisition, ensuring that power plants operate efficiently and safely. In this comprehensive guide, we will delve into the intricacies of SCADA system analysis for power plants, highlighting its importance, components, benefits, and future trends. This article will provide valuable insights for engineers, plant operators, and anyone interested in the energy sector.

Basics of SCADA Systems

What is a SCADA System?

A SCADA system is a computer-based control system used to monitor and manage industrial processes. It collects data from sensors and instruments located at remote sites and transmits this data to a central computer for analysis and control. SCADA systems are essential for the efficient operation of various industrial applications, including power plants, water treatment facilities, and manufacturing processes.

Components of a SCADA System:

- Sensors and Actuators: Measure and control process variables.

- Remote Terminal Units (RTUs): Collect data from sensors and transmit it to the central system.

- Master Terminal Units (MTUs): Central control unit that processes data and sends commands to RTUs.

- Human-Machine Interface (HMI): Interface through which operators interact with the system.

SCADA systems have evolved significantly since their inception in the mid-20th century. Early SCADA systems were limited by the technology of the time, but modern systems leverage advanced computing and communication technologies to offer sophisticated control and monitoring capabilities.

How Do SCADA Systems Work?

SCADA systems operate by continuously collecting data from various sensors installed throughout a power plant. This data is then transmitted to RTUs, which process and relay it to MTUs. The MTUs analyze the data and, based on pre-set conditions, send commands back to the RTUs to control the plant’s operations.

Communication Protocols:

- Modbus: One of the oldest and most widely used protocols in SCADA systems.

- DNP3 (Distributed Network Protocol): Commonly used in the electric utility industry.

- IEC 60870: International standard protocol used in power systems.

By enabling real-time data acquisition and control, SCADA systems ensure that power plants can respond promptly to changing conditions, maintain optimal performance, and prevent failures.

SCADA Systems in Power Plants

Role of SCADA Systems in Power Plants

In power plants, SCADA systems are indispensable. They provide comprehensive monitoring and control of various processes, from the generation of electricity to its distribution. By integrating SCADA systems, power plants can achieve higher efficiency, reliability, and safety.

Functions of SCADA Systems in Power Plants:

- Monitoring: Continuous observation of parameters such as voltage, current, and temperature.

- Control: Automated regulation of equipment to maintain desired operating conditions.

- Data Logging: Recording historical data for analysis and reporting.

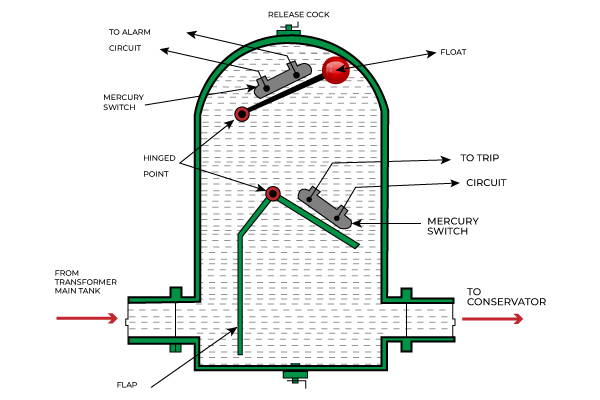

- Alarming: Alerting operators to abnormal conditions or failures.

Key Components of Power Plant SCADA Systems

SCADA systems in power plants consist of several key components that work together to ensure seamless operation.

Sensors and Actuators:

- Temperature Sensors: Measure the temperature of various components.

- Pressure Sensors: Monitor pressure levels in boilers and turbines.

- Flow Meters: Track the flow of water, steam, and fuel.

Remote Terminal Units (RTUs):

- Function: Collect data from sensors and transmit it to the central control system.

- Placement: Distributed throughout the plant to cover all critical areas.

Master Terminal Units (MTUs):

- Function: Centralized processing and control unit.

- Capabilities: Advanced data analysis, decision-making, and command issuance.

Human-Machine Interface (HMI):

- Interface: Graphical user interface for operators.

- Features: Real-time data visualization, control functions, and alarm management.

These components work in tandem to ensure that the power plant operates smoothly, efficiently, and safely.

Benefits of SCADA Systems in Power Plants

Operational Efficiency

SCADA systems enhance the operational efficiency of power plants by providing real-time data and automated control.

Real-time Monitoring and Control:

- Instant Feedback: Operators receive immediate feedback on plant conditions.

- Automated Adjustments: SCADA systems can make automatic adjustments to maintain optimal performance.

Predictive Maintenance:

- Condition Monitoring: Continuous monitoring of equipment health.

- Early Detection: Identifying potential issues before they become critical.

Improved Safety

Safety is paramount in power plant operations, and SCADA systems significantly contribute to enhancing safety measures.

Early Detection of Faults and Anomalies:

- Continuous Monitoring: Detecting deviations from normal operating conditions.

- Alarm Systems: Immediate alerts for operator intervention.

Automated Shutdown and Safety Procedures:

- Emergency Protocols: Automatic execution of safety protocols in case of critical failures.

- Fail-Safe Mechanisms: Ensuring that the plant shuts down safely during emergencies.

Cost Savings

Implementing SCADA systems can lead to substantial cost savings for power plants.

Reduction in Manual Labor:

- Automation: Reducing the need for manual monitoring and control.

- Remote Management: Allowing operators to manage the plant from a central location.

Energy Optimization:

- Efficient Operation: Ensuring that equipment operates at optimal conditions.

- Resource Management: Better management of fuel and other resources.

SCADA System Analysis for Power Plants

Why Conduct SCADA System Analysis?

Conducting a SCADA system analysis is vital for maintaining and improving system performance. Regular analysis helps identify areas for improvement, ensuring that the system operates efficiently and effectively.

Importance of System Performance Assessment:

- Optimization: Identifying inefficiencies and optimizing processes.

- Reliability: Ensuring continuous and reliable operation.

Steps in SCADA System Analysis

Data Collection and Logging:

- Historical Data: Gathering data from past operations for trend analysis.

- Real-time Data: Continuous monitoring of current conditions.

Performance Metrics and KPIs:

- Key Performance Indicators (KPIs): Metrics such as uptime, response time, and efficiency.

- Benchmarking: Comparing performance against industry standards.

Analyzing System Performance:

- Trend Analysis: Identifying patterns and trends in data.

- Root Cause Analysis: Investigating the causes of anomalies and failures.

Reporting and Recommendations:

- Comprehensive Reports: Detailed analysis of findings.

- Actionable Recommendations: Practical suggestions for improvements.

Common Challenges in SCADA Systems

Security Risks

SCADA systems are susceptible to various security risks, which can compromise their integrity and reliability.

Cybersecurity Threats and Mitigation:

- Common Threats: Malware, ransomware, and unauthorized access.

- Mitigation Strategies: Implementing firewalls, encryption, and access controls.

Protecting Against Unauthorized Access:

- Authentication: Strong authentication mechanisms.

- Access Control: Limiting access to authorized personnel only.

Integration Issues

Integrating SCADA systems with existing infrastructure can pose several challenges.

Compatibility with Existing Systems:

- Legacy Systems: Ensuring compatibility with older equipment.

- Standards Compliance: Adhering to industry standards and protocols.

Ensuring Seamless Integration:

- System Testing: Thorough testing before full implementation.

- Continuous Monitoring: Regular monitoring to detect and resolve issues.

Maintenance Challenges

Maintaining SCADA systems requires regular updates and upgrades to ensure optimal performance.

Regular Updates and Upgrades:

- Software Updates: Keeping software up-to-date with the latest patches.

- Hardware Upgrades: Replacing outdated hardware components.

Managing Downtime:

- Scheduled Maintenance: Planning maintenance activities to minimize downtime.

- Redundancy: Implementing redundant systems to ensure continuous operation.

Future Trends in SCADA Systems for Power Plants

Emerging Technologies

The future of SCADA systems in power plants looks promising with the integration of emerging technologies.

Integration with IoT and AI:

- Internet of Things (IoT): Connecting more devices for enhanced data collection.

- Artificial Intelligence (AI): Using AI for predictive analytics and decision-making.

Cloud-Based SCADA Systems:

- Advantages: Scalability, cost-efficiency, and remote access.

- Challenges: Data security and latency issues.

Advances in Cybersecurity

As cyber threats continue to evolve, advancements in cybersecurity are crucial for protecting SCADA systems.

Enhanced Security Protocols:

- Advanced Encryption: Stronger encryption methods to secure data.

- Intrusion Detection Systems (IDS): Real-time detection of security breaches.

Real-Time Threat Detection:

- Machine Learning: Using machine learning algorithms to detect anomalies.

- Automated Response: Automated systems respond to threats immediately.

Case Studies and Examples

Successful Implementation of SCADA Systems in Power Plants

Example 1: Improved Efficiency in a Thermal Power Plant:

- Case Study: A thermal power plant implemented a SCADA system to monitor and control operations.

- Outcome: Significant improvement in operational efficiency and reduced downtime.

Example 2: Enhanced Safety in a Nuclear Power Plant:

- Case Study: A nuclear power plant used a SCADA system to enhance safety protocols.

- Outcome: Improved safety measures and faster response to potential hazards.

Lessons Learned from SCADA System Failures

Analysis of a Major SCADA Failure:

- Case Study: Examination of a SCADA system failure in a power plant.

- Findings: Identification of the root causes and contributing factors.

Preventative Measures and Best Practices:

- Recommendations: Implementing best practices to prevent similar failures.

- Lessons Learned: Insights gained from the failure analysis.

Conclusion

Summary of Key Points

SCADA systems are essential

for the efficient and safe operation of power plants. They provide real-time monitoring and control, enhance safety, and contribute to significant cost savings. Conducting regular SCADA system analysis helps maintain optimal performance and identifies areas for improvement.

Looking Ahead

The future of SCADA systems in power plants is bright, with emerging technologies and advancements in cybersecurity paving the way for more efficient and secure operations. By staying updated with the latest trends and best practices, power plants can continue to leverage SCADA systems to achieve higher efficiency and reliability.

Additional Resources

Further Reading and References

For more information on SCADA systems and their applications in power plants, check out the following resources:

Frequently Asked Questions (FAQs)

What is a SCADA system used for in a power plant? SCADA systems are used for monitoring and controlling various processes in a power plant to ensure efficient and safe operation.

How do SCADA systems improve power plant efficiency? SCADA systems provide real-time data and automated control, allowing for immediate adjustments and predictive maintenance, which enhances efficiency.

What are the main components of a SCADA system in a power plant? The main components include sensors, RTUs, MTUs, and HMIs.

Call to Action

Get In Touch

If you need more detailed analysis or consultation on SCADA systems for your power plant, don’t hesitate to contact us.

This blog post outline and initial section aim to provide a thorough understanding of SCADA system analysis for power plants, incorporating valuable information, practical examples, and links to additional resources. By following this structure and expanding on each section, the article will offer comprehensive insights and rank well for the target keyword.