Introduction

What is an Oil Circuit Breaker?

Circuit breakers are crucial components in electrical systems, designed to protect electrical circuits from damage caused by overload or short circuits. Among the various types, oil circuit breakers (OCBs) hold a significant place due to their reliability and effectiveness. This guide delves deep into the world of oil circuit breakers, exploring their working principles, components, advantages, and much more.

What is an Oil Circuit Breaker?

Definition of Oil Circuit Breaker

An oil circuit breaker is a type of circuit breaker where oil is used as the arc-quenching medium. When a fault occurs, the contacts within the breaker separate, and an arc forms. The oil serves two primary purposes: it cools the arc and forms a hydrogen gas bubble, which acts as an insulator, extinguishing the arc. Historically, oil circuit breakers have been vital in the development of reliable and efficient electrical systems.

Historical Development of Oil Circuit Breakers

The concept of using oil in circuit breakers dates back to the early 20th century. Initially, bulk oil circuit breakers were common, utilizing a significant amount of oil to quench the arc. Over time, advancements led to the development of minimum oil circuit breakers, which use less oil while maintaining effectiveness. This evolution marked a significant leap in the efficiency and safety of electrical systems.

Types of Oil Used in OCBs

The oil used in oil circuit breakers is usually mineral oil. It is selected for its excellent insulating properties and ability to dissipate heat. The oil must be free from impurities to maintain its dielectric strength and ensure reliable operation. Regular testing and maintenance are crucial to monitor the quality of the oil and prevent any potential issues.

How Does an Oil Circuit Breaker Work?

Working Principle of Oil Circuit Breakers

Oil circuit breakers operate by utilizing oil to extinguish the arc formed when the contacts separate. Here’s a detailed look at the working principle:

- Fault Detection: When a fault occurs, the relay system detects it and sends a signal to the circuit breaker to operate.

- Contact Separation: The contacts within the breaker separate, forming an arc.

- Arc Formation: The electrical current ionizes the surrounding oil, creating an arc.

- Arc Quenching: The oil rapidly decomposes into hydrogen gas, which is released around the arc. This gas forms a bubble, effectively cooling the arc and reducing its energy.

- Extinguishing the Arc: The hydrogen bubble and the oil work together to extinguish the arc, interrupting the current flow.

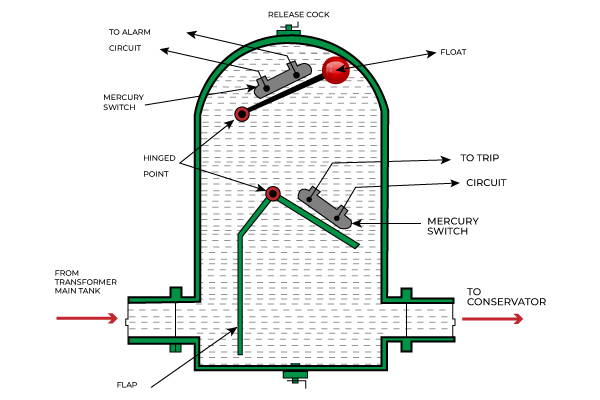

Diagram Illustrating the Working of an OCB

The diagram above shows the key components involved in the operation of an oil circuit breaker. It highlights how the contacts, oil, and arc interact to ensure safe and efficient current interruption.

Components of an Oil Circuit Breaker

Key Components of an Oil Circuit Breaker

Oil circuit breakers consist of several essential components, each playing a critical role in their operation. Understanding these components is vital for grasping how OCBs function and are maintained.

Tank

The tank houses the oil and the interrupter unit. It is typically made of metal and designed to withstand high pressure. The tank also provides insulation and ensures that the oil remains contained.

Interrupter Unit

The interrupter unit is the core of the oil circuit breaker. It contains the moving and fixed contacts and is responsible for interrupting the current. There are different types of interrupter units, including single-break and multiple-break types, depending on the design and application.

Moving and Fixed Contacts

The contacts are crucial for the operation of the circuit breaker. The moving contacts are connected to a mechanism that allows them to separate from the fixed contacts when a fault is detected. This separation initiates the arc, which is then extinguished by the oil.

Oil

The oil used in oil circuit breakers is mineral oil, chosen for its insulating and cooling properties. It must be regularly tested and maintained to ensure it remains free of impurities, which can affect its performance.

Arc Chute

The arc chute is designed to guide and cool the arc, aiding in its extinction. It helps in efficiently dissipating the heat generated by the arc and ensures that the arc is safely quenched.

Types of Oil Circuit Breakers

Different Types of Oil Circuit Breakers

There are primarily two types of oil circuit breakers: bulk oil circuit breakers and minimum oil circuit breakers. Each type has its unique characteristics and applications.

Bulk Oil Circuit Breakers

Bulk oil circuit breakers use a large volume of oil for arc quenching and insulation. They are typically used in high voltage applications and are known for their robust design. However, they require significant maintenance and have a higher risk of oil leakage.

Minimum Oil Circuit Breakers

Minimum oil circuit breakers use a smaller amount of oil, making them more compact and efficient. They are designed to provide the same level of performance as bulk oil circuit breakers but with reduced maintenance and lower risk of oil-related issues.

Comparison Between Bulk and Minimum Oil Circuit Breakers

| Feature | Bulk Oil Circuit Breaker | Minimum Oil Circuit Breaker |

|---|---|---|

| Volume of Oil | High | Low |

| Maintenance | High | Low |

| Risk of Oil Leakage | Higher | Lower |

| Applications | High Voltage | High and Medium Voltage |

| Size | Large | Compact |

Understanding the differences between these types helps in selecting the right circuit breaker for specific applications.

Advantages and Disadvantages of Oil Circuit Breakers

Pros and Cons of Oil Circuit Breakers

Oil circuit breakers offer several advantages but also come with some drawbacks. It’s important to weigh these factors when considering their use in electrical systems.

Advantages

- High Dielectric Strength: Oil has excellent insulating properties, making it effective in extinguishing arcs.

- Effective Arc Quenching: The decomposition of oil into hydrogen gas helps in rapidly quenching the arc.

- Reliability and Durability: Oil circuit breakers are known for their reliable performance and long service life.

Disadvantages

- Maintenance Requirements: Regular maintenance is necessary to ensure the oil remains clean and effective.

- Risk of Oil Leakage and Fire Hazards: Oil can leak, and there is a potential risk of fire, especially if the oil is not properly maintained.

- Environmental Concerns: The disposal of used oil poses environmental challenges, and there is a push towards more eco-friendly alternatives.

Applications of Oil Circuit Breakers

Oil circuit breakers are used in various applications, ranging from industrial settings to utility and power distribution networks. Their ability to handle high voltage makes them suitable for critical applications.

Industrial Applications

In industrial settings, oil circuit breakers protect machinery and electrical systems from overloads and short circuits. They ensure the safe operation of equipment and prevent costly downtime due to electrical faults.

Utility and Power Distribution

Utilities use oil circuit breakers in power distribution networks to manage the flow of electricity and protect infrastructure. They are crucial in substations and high voltage transmission lines, ensuring the stability and reliability of the power supply.

High Voltage Applications

Oil circuit breakers are particularly effective in high voltage applications due to their robust design and high dielectric strength. They are used in various high voltage scenarios, including power plants and large industrial complexes.

Maintenance of Oil Circuit Breakers

How to Maintain Oil Circuit Breakers

Proper maintenance is essential for the reliable operation of oil circuit breakers. Regular inspections and servicing help prevent faults and extend the lifespan of the equipment.

Regular Inspection Protocols

Regular inspections should include checking the oil level, examining the contacts, and inspecting the tank for any signs of wear or damage. These inspections help identify potential issues before they lead to failures.

Oil Testing and Replacement

Oil should be tested periodically to ensure it retains its insulating properties. Tests include checking for moisture, acidity, and dielectric strength. If the oil quality is compromised, it should be replaced to maintain the breaker’s performance.

Cleaning and Servicing Contacts

Contacts should be cleaned regularly to remove any carbon deposits or other contaminants. Proper servicing ensures that the contacts operate smoothly and effectively interrupt the current when necessary.

Safety Precautions During Maintenance

When performing maintenance, it is important to follow safety protocols to prevent accidents. This includes wearing appropriate protective gear, ensuring the breaker is de-energized, and following proper procedures for handling and disposing of used oil.

For more detailed maintenance guidelines, refer to this resource.

Comparison with Other Types of Circuit Breakers

Oil Circuit Breakers vs Other Circuit Breakers

Oil circuit breakers are one of several types of circuit breakers available. Here’s how they compare to other popular types.

Oil Circuit Breakers vs Air Circuit Breakers

Air circuit breakers use air as the arc-quenching medium. They are commonly used in low and medium voltage applications.

| Feature | Oil Circuit Breaker | Air Circuit Breaker |

|---|---|---|

| Arc Quenching Medium | Oil | Air |

| Applications | High Voltage | Low/Medium Voltage |

| Maintenance | High | Low |

| Environmental Impact | Higher | Lower |

Oil Circuit Breakers vs Vacuum Circuit Breakers

Vacuum circuit breakers use a vacuum to extinguish the arc. They are known for their high efficiency and low maintenance requirements.

| Feature | Oil Circuit Breaker | Vacuum Circuit Breaker |

|---|---|---|

| Arc Quenching Medium | Oil | Vacuum |

| Applications | High Voltage | High/Medium Voltage |

| Maintenance | High | Low |

| Environmental Impact | Higher |

Lower |

Oil Circuit Breakers vs SF6 Circuit Breakers

SF6 circuit breakers use sulfur hexafluoride gas to quench the arc. They are widely used in high-voltage applications due to their excellent performance.

| Feature | Oil Circuit Breaker | SF6 Circuit Breaker |

|---|---|---|

| Arc Quenching Medium | Oil | SF6 Gas |

| Applications | High Voltage | High Voltage |

| Maintenance | High | Moderate |

| Environmental Impact | Higher | Lower, but SF6 is a potent greenhouse gas |

Understanding these comparisons helps in choosing the right type of circuit breaker for specific needs and applications.

Future of Oil Circuit Breakers

Future Trends in Oil Circuit Breakers

The future of oil circuit breakers is influenced by technological advancements and environmental considerations.

Technological Advancements

Innovations in materials and design are leading to more efficient and reliable oil circuit breakers. Enhanced monitoring systems and improved oil formulations are some of the areas where advancements are being made.

Innovations in Oil Types and Materials

Research is ongoing to develop alternative insulating oils that are more environmentally friendly. These new oils aim to retain the performance characteristics of traditional mineral oil while reducing environmental impact.

Environmental Considerations and Alternatives

As environmental regulations become stricter, there is a push towards finding alternatives to oil circuit breakers. This includes exploring other types of circuit breakers, such as vacuum and SF6 breakers, which have a lower environmental footprint.

Frequently Asked Questions (FAQs) About Oil Circuit Breakers

FAQs on Oil Circuit Breakers

What is the lifespan of an oil circuit breaker?

The lifespan of an oil circuit breaker can vary depending on the operating conditions and maintenance. Typically, they can last for several decades with proper maintenance.

How often should the oil in an OCB be replaced?

Oil should be tested periodically, and its replacement frequency depends on the test results. Generally, oil may need to be replaced every 5 to 10 years, depending on the operating conditions.

Are oil circuit breakers safe to use in residential settings?

Oil circuit breakers are generally used in industrial and high-voltage applications. For residential settings, other types of circuit breakers, such as air or miniature circuit breakers, are more suitable.

Can oil circuit breakers be recycled or disposed of safely?

Yes, oil circuit breakers can be recycled. The oil should be handled and disposed of according to environmental regulations. Many manufacturers provide guidelines for the safe disposal and recycling of oil circuit breakers.

Conclusion

Summarizing Oil Circuit Breakers

Oil circuit breakers are essential components in high-voltage electrical systems. Their ability to effectively quench arcs and provide reliable performance makes them invaluable in various applications. While they come with certain maintenance requirements and environmental considerations, advancements in technology continue to improve their efficiency and sustainability.

Learn More About Electrical Safety and Equipment

For more detailed information on electrical safety and equipment, subscribe to our newsletter and stay updated with the latest insights. Feel free to ask questions or share your experiences in the comments section below.

References

Additional Resources

- Understanding Circuit Breakers

- Oil Circuit Breaker Maintenance Guidelines

- Comparing Different Types of Circuit Breakers

Feel free to ask for any specific sections or further elaborations.